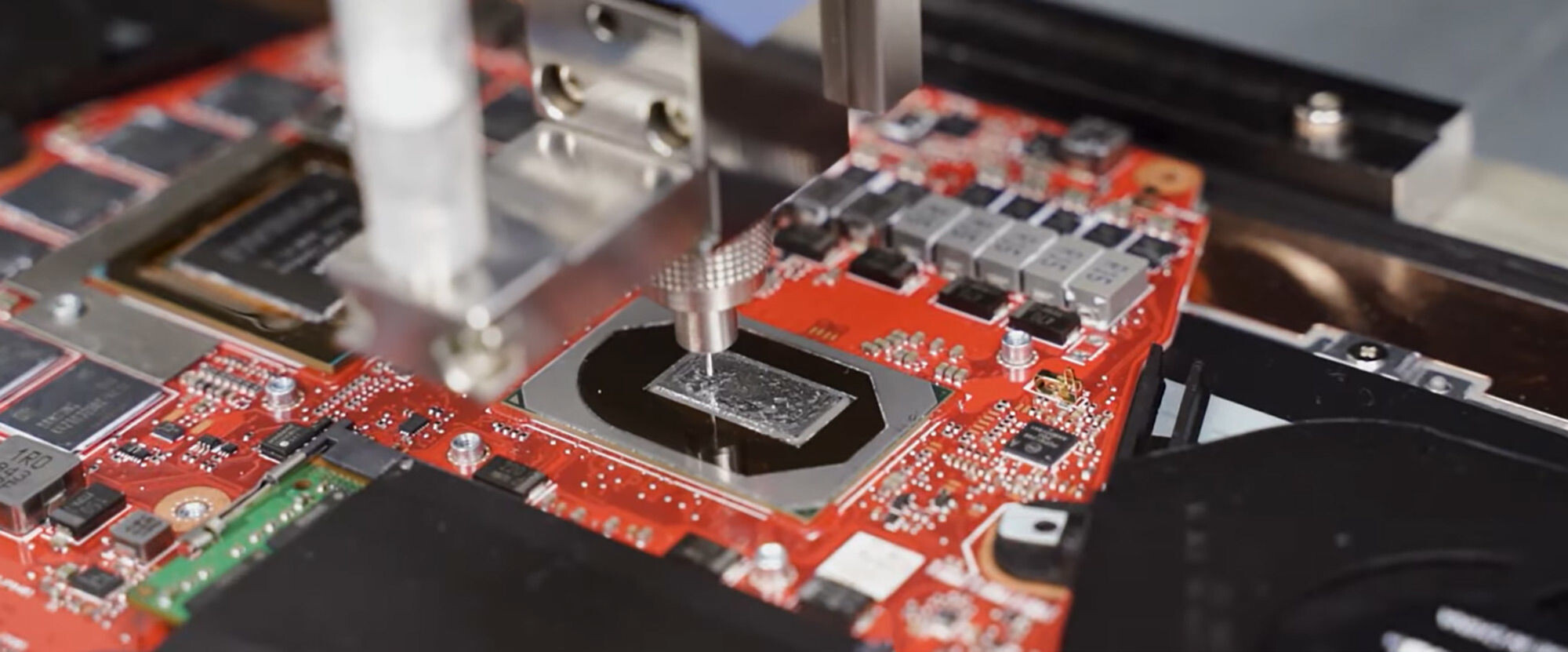

In this thermal analysis of Intel’s i9-7900X, we’ll benchmark liquid metal application on a delidded CPU versus a stock CPU with thermal paste, then determine whether the delid was “worth it.” The goal then, of course, is to explore whether Intel should offer better thermal solutions on their HEDT CPUs. By deploying liquid metal as an analog for “anything better,” we can illustrate the potential for (1) improved operation of the CPU through reduced thermal load on the die, (2) cheaper cooling solutions by removing the brute force requirement presently in place, and resultingly lower noise emission, and (3) increased overclocking headroom.

#Best liquid metal thermal paste series

This is part one of a two-part series that’s dedicated to exploring the efficacy of Intel’s TIM on HEDT CPUs, starting with the i9-7900X. It’s not, though, and that’s what we’re setting forth to prove today.

If the Dow Corning TIM is “good enough,” then there’s really no reason to change it. Part of encouraging a change is proving that there’s reason to change. Intel has used solder before – there’s precedent for it – and certainly there exist thermal solutions with greater transfer capabilities than what’s used on most of Intel’s CPUs. The usable life of the platform will expire prior to the CPU’s operability, in essence.īut that doesn’t mean there aren’t better solutions. To the credit of both Intel and Dow Corning, the TIM selected is highly durable to thermal cycling – it’ll last a long time, won’t need replacement, and shouldn’t exhibit any serious cracking or aging issues in any meaningful amount of time. Once we start looking at the 7900X and other CPUs of a similar class, the ability to argue in favor of Dow Corning’s TIM weakens. With an i7-7700K, TIM is perhaps more defensible – it’s certainly cheaper, and that’s a cheaper part. Intel’s statement pertaining to usage of TIM on HEDT (or any) CPUs effectively paraphrases as “as this relates to manufacturing process, we do not discuss it.” Intel sees this as a proprietary process, and so the subject matter is sensitive to share. What we do know, and what we can test, is the efficacy of the TIM as opposed to alternatives. Using TIM could be a matter of cost – as seems to be the default assumption – and spend, it could be an undisclosed engineering challenge to do with yields (with solder), it could be for government or legal grants pertaining to environmental conscientiousness, or related to conflict-free advertisements, or any number of other things. Thus, the Liquid Extreme is also suitable for use in absolute high-end systems.There are many reasons that Intel may have opted for TIM with their CPUs, and given that the company hasn’t offered a statement of substance, we really have no exact idea of why different materials are selected. Since the thermal grease does not require any silicones or oils as a carrier, the classic problem of timely desiccation does not exist. The new thermal grease offers through its creamy consistency an even easier handling and of course an excellent thermal conductivity.Īn important aspect in the development of the new Liquid Extreme was the long-term stability in addition to the ease of use and the high performance. The Liquid Extreme is – like all other articles by Coollaboratory – developed and produced in Germany. Due to the paste-like texture the application is very easy now. It’s made of 100% metal, but it has an absolute new usability and offers an outstanding performance.

#Best liquid metal thermal paste pro

After the outstanding thermal compounds Liquid Pro and Ultra, Coollaboratory presents the next generation of liquid metal thermal compounds with the brand new Coollaboratory Liquid Extreme.

0 kommentar(er)

0 kommentar(er)